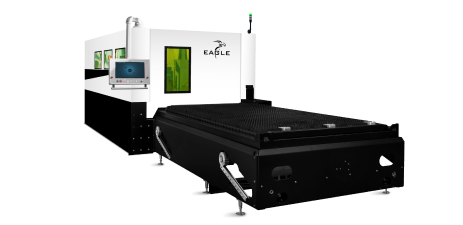

Eagle Fiber Laser Systems

You are invited to soar with Eagle.

In 2006 Marcin Ejma founded Eagle with the sole purpose to build the most efficient cutting system in the market. Two years later (2008), Marcin Ejma presented a fiber laser cutting system at EuroBLECH when most metal processing manufacturers were still promoting CO2 lasers, plasma, and other older technologies. Over the last sixteen years Eagle has expanded from its headquarters in Walcz, Poland to Germany, Italy and Scandinavia. They are also proudly represented by distributors in over 25 countries.

Eagle’s engineering teams have developed the fastest and most powerful fiber laser machines in the marketplace. They were the first laser manufacturer to launch award winning 6kW, 8kW, 10kW, 12kW, 20kW, and now 30kW laser cutting systems. Eagle certainly believes in forward thinking and optimizing productivity through effective innovation. They design their fiber laser machines for longevity, reliability and unmatched productivity. They use the highest quality parts and make them available to their customers at affordable prices.

Eagle is an award-winning company. They manufacture EAGLE brand fiber laser cutting systems – the most innovative systems available today. Eagle embarked on a tour in various European destinations, including Barcelona, Bilbao, Italy, Poland, Germany and Romania to showcase their leading edge machines. Eagle is now recognized as a world class manufacturer of fiber laser machines and supplies these state-of-the art machines throughout Europe & North America. They continue to meet the industry's challenge for faster, more efficient, and reliable laser-cutters.

Since 2006 when Eagle began operations they have been a trail blazer to reckon with. State-of-the-art fiber laser machines lower production time and consume less energy. Eagle believes higher power means higher profits and that is the direct link to Eagle’s mandate of increasing profits for industrial manufacturing. The iNspire 30kW is the fastest fiber laser cutting system available today, with 6G acceleration, patented Eagle eVa cutting head, a super-light carbon fiber traverse, linear motors on all axes, and the unmatched 9-second pallet changer.

Eagle Fiber Lasers

Comparison of Key Features

| iNspire | eVision | eSmart | |

| Maximum laser power | 30 [kW] | 30 [kW] | 10 [kW] |

| Acceleration | 6 [g] | 3 [g] | 2 [g] |

| Positioning speed | 350 [m/mm] | 180 [m/mm] | 170 [m/mm] |

| Pallet changing time | 9 [s] | 9 [s] | 25 [s] |

| Distance between nozzle and cover slide | 355 [mm] | 355 [mm] | 305 [mm] |

What makes Eagle Fly High

eVa Cutting Head

Designed to withstand the harshest of conditions the eVa is the first cutting head to eliminate all internal moving parts thereby almost eliminating any chance of contamination. The patented eVa head features only three consumable parts.

Linear Motors

Designed to provide unbeatable precision, acceleration, and dynamic accuracy, linear motors don’t require racks and pinions, gearboxes, or ball-screws. These motors deliver the same accuracy, even after ten years of operation and are built to last due to their unique design.

IPG

Both the laser and chiller are integrated into the Eagle diagnostic system to ensure high performance cutting and reliable operation. IPG laser sources feature low energy consumption while maintaining reduced operating costs, higher efficiency, and increased productivity. Quality always comes first when you fly with Eagle.

© 2023 Paramount Machinery Inc. All rights reserved.