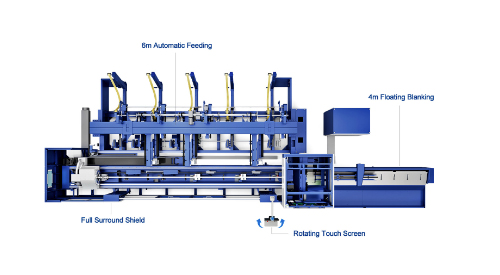

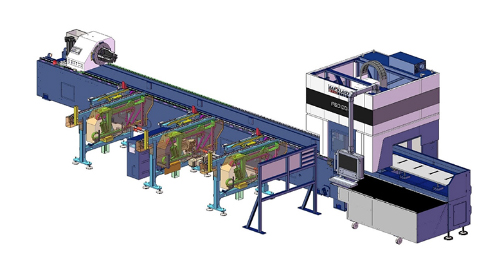

Han’s Fiber Laser Tube-Cutting Systems– PD Series

Han’s PD Tube Fiber Laser (1kW-6kW) is designed to cut a variety of metal pipes like round tube, square tube, rectangular tube, and angle and channel steel profiles. It’s perfectly suited for metal furniture, display shelves, agricultural machinery, and fitness equipment manufacturing. It is undoubtedly the most popular pipe laser cutting system in the metal pipe processing industry for its professional-grade capabilities, fast operation, efficiency, and cost-effective performance.

CUTTING HEAD

Han’s state-of-the-art Fiber laser cutting head features a single-lens chamber with a 5″ cutting head and an advanced sensor for high performance and cut accuracy. It is also equipped with high-resolution, high-precision servo motors for the X, Y, and Z linear axes and A/B rotary axes providing excellent precision and increased torque. These features ensure stable performance at high processing speeds and acceleration.

CLAMPING SYSTEM

Han’s advanced Clamping System comes with a real-time digital monitoring system to identify the pipe size being clamped. It also intelligently maintains the pressure even when the air supply is cut-off. The mechanical transmission of the clamping system is designed to reliably run for continuous 24-hour production cycles.

Why Choose PD Series

The PD series Fiber Laser tube-cutting machine excels in efficiency and precision with advanced laser, engineering, and control technologies for cutting a variety of metal pipes. This tube laser cutter is equipped to cut both large heavy-duty pipe and small tubes. It features a robust horizontal structure with high-precision components and automatic loading capabilities, enhancing productivity. The system includes a secure clamping mechanism with digital monitoring, a rear chuck designed for thermal stability, and multiple feeding options, both automatic and semi-automatic, ensuring optimal operation and accuracy.

Automation Systems (Optional)

Get the most out of your PD Series with the following systems Automatic Loading System: Stack bundles of tube in a strap-based holding zone and automatically handle the loading and feeding processes. A pipe length detection device guides the chuck to the proper clamping position. Semi-automatic Feeding System: Place an entire row of pipes manually on the material rack, and they will be automatically fed to the clamping position on the X-axis bed. A photoelectric detection device on the mobile chuck ensures that the pipes reach the correct clamping position. Floating Support - Unloading (4m or 2.5m): The cut workpiece smoothly gets collected into the parts collection bin. A servo-driven support table works to support longer lengths of cut-off pipe before dropping into the bin.

Technical Data

Model | PD |

Laser Power | 1kW-6kW (customizable) |

Max. Machining Range | Φ 20-180 mm □ 20-180 mm (Optional: Φ 20-110 mm □ 20-110 mm |

Max. Speed (A/B axis) | 12r/min (Optional: 150r/min) |

X/Y Axis Rapid Traverse Speed | 120/min |

Max. Load Capacity | 574 lbs (260kg) |

Max. Material Length | 480" (12200mm) |

PD Series Han's Laser | P6010D Fiber Laser Tube Cutting Machine

Request for Consultation

© 2023 Paramount Machinery Inc. All rights reserved.