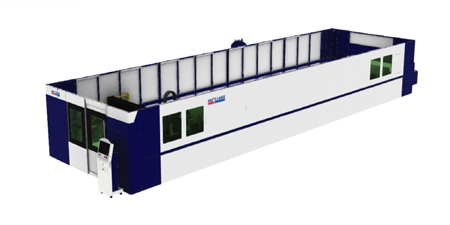

Giant HLB Series

The fully enclosed HLB large format series laser cutter is designed for 13M+ long and 20mm+ thick metal plate cutting. Han's advanced 901 controller system enables fabricators to cut large pieces of metal fast with innovative nesting features that provide almost 8% material savings on every batch. These machines also offer superior finish in high volume metal cutting. Han’s HLB Series Fiber Lasers with 12kW, 20kW or 30kW of laser power are clear choices to boost profits for your shop.

BOSCH-REXROTH CNC SYSTEM

Bosch-Rexroth designs the highest performing CNC and motion control systems in the market. Han’s 901 real-time CNC controller leverages this technology along with Rexroth motors that are coupled with an optimized frame and gantry system. This allows the HF Expert 2D lasers to reach extremely high speeds and acceleration to efficiently cut high-quality parts.

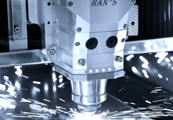

HAN’S INTELLIGENT CUTTING HEAD

Han’s has developed a complete range of reliable high power auto-focus cutting heads that include standard and bevel models . They have a lean design with excellent optical configuration that supports smooth airflow for improved cutting efficiency and quality. A patented dust-proof technology offers longer lens life.

HAN’S LASER SOURCE

Han’s 4kW – 30kW laser sources from Han’s Photonics. They are equipped with a new generation control system which is user-friendly and offers real-time internal monitoring, fast data feedback response, and modulation pulse response in microseconds. You also have the option of using IPG Photonics or Max Photonics as the laser source for this machine.

Stable and Reliable

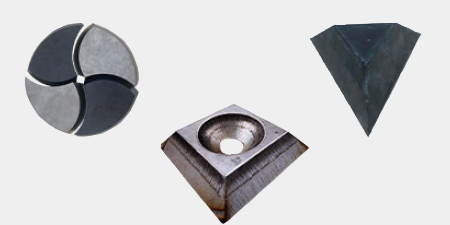

The strong outer cover is ergonomically designed to complement the smart zoning ventilation for dust removal. The modularly assembled cutting platform is fully separated from the machine bed to eliminate thermal effects of high-power laser cutting. An automatic Backlash compensation system ensures accurate transmission for long runs over long and wide plates . The HLB also features automatic swing correction of axis and bevel mechanism which enables fabricators to cut straight edge grooves, arc grooves, V slopes, A slopes, Y slopes, X slopes and K slopes.

Leading Cutting Technology

HF Giant series’ advanced zero-second perforation technology, fly-cutting , leap-frog cutting technology, and compressed air cutting ability for stainless steel improve efficiency and produce superior cuts on highly reflective non-ferrous metal materials such as, , aluminum alloy, aluminum-zinc-coated plate, pure aluminum, brass, and copper.

Max Power

Max. Acceleration

Max. Positioning Speed

Precision

Technical Data

Model | G12030HLB/G13030HLB/G24045HLB |

Laser Power | 12kW/20kW/30kW |

Working Area | 8000mmx50,000mm (customizable length) |

Positioning Accuracy | 2500mmx5000mm (customozable length) |

Repeatability | X-axis ±0.11mm Y-axis:±0.06mm |

Max. Positioning Speed | X-axis:0.07mm Y-axis:0.05mm |

Max. Acceleration | 80m/min |

Bevel Angle | 0.8G |

Groove Typw | 0-45° |

| V-Y-X-K cut and gradual bevel |

Request for Consultation

© 2023 Paramount Machinery Inc. All rights reserved.