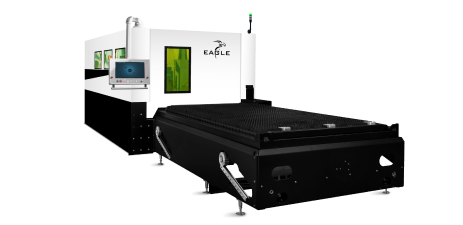

eSmart Fiber Laser

Eagle’s eSmart fiber laser is affordably priced for even the smallest shop to economically introduce fiber laser technology and leverage its capabilities to improve productivity.

eVa Cutting Head

Designed to withstand the harshest of conditions the eVa is the first cutting head to eliminate all internal moving parts thereby almost eliminating any chance of contamination. The patented eVa head features only three consumable parts.

Linear Motors

Designed to provide unbeatable precision, acceleration, and dynamic accuracy, linear motors don’t require racks and pinions, gearboxes, or ball-screws. These motors deliver the same accuracy, even after ten years of operation and are built to last due to their unique design.

IPG

Both the laser and chiller are integrated into the Eagle diagnostic system to ensure high performance cutting and reliable operation. IPG laser sources feature low energy consumption while maintaining reduced operating costs, higher efficiency, and increased productivity. Quality always comes first when you fly with Eagle.

Low investment cutting edge technology

Economical, efficient and easy-to-use. The eSmart series allows users to bring the latest cutting technology into their equipment mix. By far the best value Fiber Laser cutting system for metal shops that want the latest technology on a lower investment budget.

Uncompromising Speed and Quality

Features a smaller footprint and cuts parts with high surface quality & accuracy while maintaining a very high dynamic cutting process. The eSmart lasers are equipped with a body made of composite material for maximum stability and automation upgrades to improve productivity.

kw

Max. laser source power

g

Max. acceleration

m/min

Max. positioning speed

mm

Cutting accuracy

m/min

Max. cutting speed

mm

Repeat accuracy

Work Area

Model |

| 1530 | 2040 |

X-axis | [mm] | 3060 | 4070 |

Y-axis | [mm] | 1540 | 2098 |

Z-axis | [mm] | 100 | 100 |

Max. sheet Weight | [kg] | 1000 | 3200 |

Dimensions and weight of the machine

Model |

| 1530 | 2040 |

Length | [mm] | 10000 | 11570 |

Width | [mm] | 3080 | 3016 |

Height | [mm] | 3060 | 2240 |

Weight | [kg] | 1810 | 2100 |

* Approximate values. The exact parameters are specified in the machine's installation plan

Maximum Cutting Thickness

Laser Source |

| 1kW | 2kW | 3kW | 4kW | 6kW | 8kW | 10kW |

Mild Steel | [mm] | 10 | 16 | 20 | 20 | 30* | 40* | 50* |

Stainless Steel | [mm] | 4 | 10 | 15 | 20 | 30* | 40* | 50* |

Aluminium | [mm] | 2 | 6 | 12 | 15 | 30 | 35 | 40 |

Brass | [t] | 2 | 4 | 6 | 8 | 12 | 15 | 20 |

copper | [mm] | 1.5 | 4 | 6 | 6 | 10 | 15 | 20 |

Maximum thicknesses of the materials to be processed. The values that are achieved depend on the quality of the material being processed, the quality of the cutting gases, the quality of the service and the NC program and the condition of the wearing parts

* Heavy duty (HD) laser cutter version with CatLine option

Media

Compressed Air Pressure | [bar] | 6 |

Nitrogen Pressure | [bar] | 25-30 |

Oxygen Pressure | [bar] | 8-10 |

Laser Source Data

Laser Type | IPG Fiber Laser | |

Available Laser Sources | [kW] | 1-10 |

Wavelength | [um] | 1.07 |

Beam Quality | Mm x mrad | 3.4-4.0 |

Frequency | [kHz] | 5 |

Video

Request for Consultation

© 2023 Paramount Machinery Inc. All rights reserved.