Han’s Fiber Laser Tube-Cutting Systems– TD Series

Han’s TD Tube Fiber Laser (2kW-6kW) is designed to cut a variety of metal pipes including mild steel, stainless steel, and aluminum alloy in round, square, oval, channel, angle, and l-beam profiles. TD Series’ compact structure maximizes space efficiency and pneumatic chucks are built for durability and precision. It also has a negative pressure dust removal system to ensure clean operations. The TD series has many powerful features that make it the ideal choice for the metal tube processing industry.

CUTTING HEAD

Han’s state-of-the-art Fiber laser cutting head features a single-lens chamber with a 5″ cutting head and an advanced sensor for high performance and cut accuracy. It is also equipped with high-resolution, high-precision servo motors for the X, Y, and Z linear axes and A/B rotary axes providing excellent precision and increased torque. These features ensure stable performance at high processing speeds and acceleration.

CLAMPING SYSTEM

Han’s advanced Clamping System comes with a real-time digital monitoring system to identify the pipe size being clamped. It also intelligently maintains the pressure even when the air supply is cut-off. The mechanical transmission of the clamping system is designed to reliably run for continuous 24-hour production cycles.

PNEUMATIC CHUCKS

The pneumatic chucks utilize a four-position roller for clamping, which includes a self-centering feature. Chuck components are made from a welded plate structure that undergoes a series of treatments to ensure excellent stability and dynamic performance.

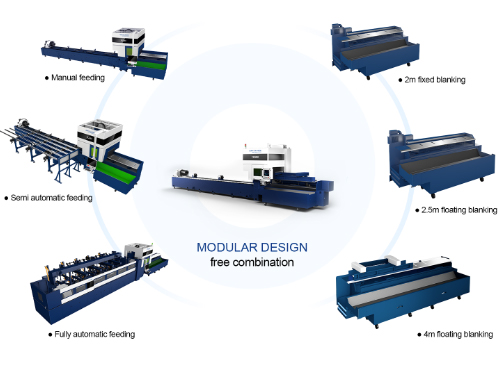

TD Series – Modular, Versatile and Efficient

The space-efficient TD series laser tube-cutter by Han’s Laser features a versatile modular loading and unloading structure, allowing users to customize the setup according to their specific requirements. The cutting machine accommodates a wide variety of shapes and sizes, including round tubes (15 to 220 mm), square tubes (15 to 150 mm), oval tubes, channel steel, angle steel, I-beams, and other special-shaped tubes. The TD series machine bed features high-precision gear racks and linear guide rails for stable and accurate transmission. It includes a blanking device to boost efficiency. A one-touch remote control facilitates manual adjustments from anywhere around the machine.

Automation Systems (Optional)

Get the most out of your TD Series with the below systems Automatic Loading System: Stack bundles of tube in a strap-based holding zone and automatically handle the loading and feeding processes. A pipe length detection device guides the chuck to the proper clamping position. Semi-automatic Feeding System: Place an entire row of pipes manually on the material rack, and they will be automatically fed to the clamping position on the X-axis bed. A photoelectric detection device on the mobile chuck ensures that the pipes reach the correct clamping position. Floating Support - Unloading (4m or 2.5m): The cut workpiece smoothly gets collected into the parts collection bin. A servo-driven support table works to support longer lengths of cut-off pipe before dropping into the bin.

Han's T6033D high-speed laser tube cutting machine

Request for Consultation

© 2023 Paramount Machinery Inc. All rights reserved.