Blog

RECENT POSTS

PMI Blog

High Powered Fiber Laser Advantages

by Eric St. James

Published at 2023-05-31

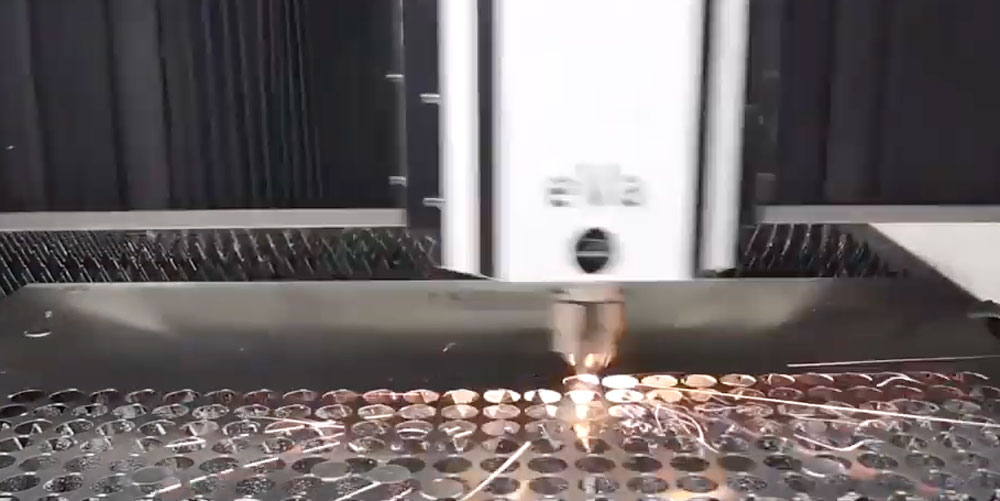

High-powered Fiber Lasers (10kW and higher for the purposes of this article) are making their way into the market and quite rightly demanding attention from fabricators across the world. Machine builders have rapidly progressed from the 2 to 4-kW laser sources to an astonishing 30kW in laser power boasting incredible cutting speeds in heavy material and increasing profitability as cost per part plummets.

Let’s look at some of the best reasons why high-powered Fiber Lasers should find their way into your shop

Faster Parts Production

High-powered Fiber Lasers offer unparalleled cutting speeds. They can deliver much higher power densities to produce more in less time. A high-powered Fiber Laser with 6G of acceleration can deliver a positioning speed of 350 m/min and cutting rates of up to 150 m/min enabling higher throughput. Increasing the laser power improves cutting speed in an almost linear fashion. Here is a comparison video of 4kW, 6kW, 8kW, 12kW, 15kW and 20kW cutting 8mm mild steel. The increase in productivity from 30kW will amaze you. The below chart also shows the impact of more laser power which results in an almost linear increase in cutting speed

Improved Cut Quality

Fabricators are finding that high-powered Fiber lasers increase the production of high-quality cut parts. Scientific research has helped to produce a very highly focussed and uniform laser beam of light (wavelength between 1000 and 1100 nanometers) to cut through metal leading to a superior finish. This process also allows for very precise cuts on very thick pieces of metal too.

Fabricators are finding that high-powered Fiber lasers increase the production of high-quality cut parts. Scientific research has helped to produce a very highly focussed and uniform laser beam of light (wavelength between 1000 and 1100 nanometers) to cut through metal leading to a superior finish. This process also allows for very precise cuts on very thick pieces of metal too.

Flexibility

The ability to use a variety of assist gasses permits more flexibility in cutting a variety of materials quickly and with improved edge quality. Along with the standard nitrogen and oxygen assist, more users are turning to shop air to lower costs while still providing excellent cut speeds and quality. Most machine builders are also offering mixing capabilities where a small percentage of oxygen is premixed with nitrogen to create a hybrid assist gas that is particularly effective in aluminum and stainless steel cutting.

Higher Profits

High-powered Fiber Lasers improve productivity and bring about higher profits. While the upfront cost may seem high, they offer significant savings over the long term. Fast cutting speeds greatly reduce the cost per part. This in turn reduces the use of gas and energy consumption. Fiber lasers also require very little maintenance and have a long lifespan. The overall reduction in operating costs result in increased profitability and higher ROI.

From their speed and precision to their flexibility and cost-effectiveness, high-powered Fiber Lasers offer a number of advantages that simply cannot be ignored.

© 2023 Paramount Machinery Inc. All rights reserved.