RECENT POSTS

PMI Blog

UHP Fiber Lasers - Are they Worth it!

by Eric St. James

Published at 2025-07-09

Laser cutting has seen incredible advancements since it came on to the scene over 50 years ago. Since the early 2010s, we’ve seen rapid adoption of 1-3kW fiber lasers. Even more recently, the trend has been towards higher and higher power thanks to the increased productivity and cut speeds provided by the higher energy. In 2015, we were seeing maximum power levels of 6kW, and just in the past few years we have seen a rapid progression to Ultra-High Powered (UHP) Fiber Lasers, defined as anything greater than 10kW, and even up to 40kW. With growing demands, labor shortages, and the need for speed and precision, it’s easy to see why these Ultra-High-Powered machines have been captivating fabricators around the world. But are they worth the investment? Let’s dig in.

Boost Medium- to High-Volume Production Throughput

It’s no secret that higher powered fiber lasers have a significant advantage on cutting speed. Ultra-High-Powered Fiber lasers truly excel in environments where speed and volume matter. They can cut parts significantly faster than under-10kW machines, especially for thick materials.

This specifically benefits shops handling repetitive, high-volume workloads. It leads to dramatically reduced cycle times, faster turnaround and the ability to take on more orders without increasing labor. Plus, the impact on part cost often translates into bigger profits.

How big are the cutting speed gains with UHP lasers?

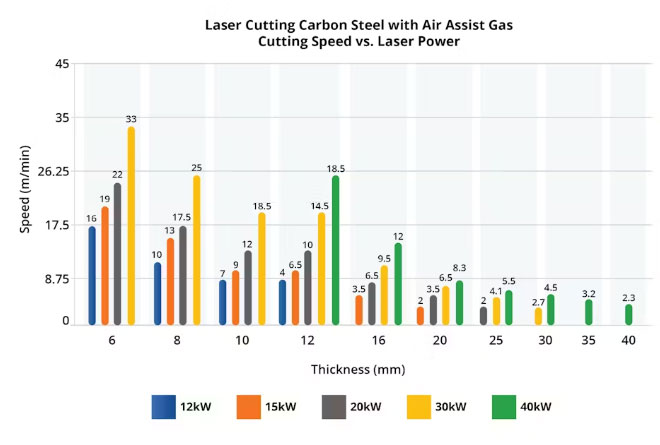

Laser Focus World tested cutting speeds for 6 - 40 mm carbon steel on 12 - 40kW lasers. They found strong increases in speed at higher power, even for thick materials. Surprisingly, the percentage gain in speed increased with metal thickness, suggesting that the highest power UHP lasers may lead to further productivity gains in thick cutting.

For example, the difference between a 15kW machine and 40kW machine is 270% increase in power. That translated to a 280% increase in cutting speed for 12mm carbon steel but a whopping 420% increase for 20mm carbon steel. Looking at 30mm carbon steel, when increasing power by 33% from 30 to 40kW, the cuts were 66% faster.

Superior Quality on Thin to Thick Materials

Speed doesn’t mean a thing unless the parts produced are high quality. Another top advantage of UHP lasers is their track record of producing consistent, high-quality edges for a variety of material thicknesses. This includes faster, cleaner cuts on thick stainless steel, aluminum and mild steel, thanks to highly focused and uniform laser beams.

Flexibility with Assist Gases: Oxygen, Nitrogen, or Compressed Air

UHP fiber lasers allow the use of multiple assist gases, giving you flexibility in cutting a variety of materials with speed and edge quality. Options include the standard nitrogen and oxygen assist gases, but also compressed air - which has been growing in popularity among fabricators due to convenience and cost savings.

In fact, Laser Focus World found that UHP lasers using high-pressure air produce fast, dross-free cuts of thick carbon steel compared to nitrogen and oxygen.

Most machine builders now offer mixing capabilities, premixing nitrogen and oxygen to create a hybrid assist gas enhancing edge quality in thicker steel plate and aluminum. Whatever assist gas makes sense for your shop, know you have the flexibility with UHP fiber lasers.

Addressing Labour Shortages and Reducing Rework

Labour shortages are a hot button topic in the metal fabrication industry - and in Canadian manufacturing and skills trades in general. Finding and retaining skilled operators is a challenge, and training new staff takes up valuable time and resources.

UHP fiber lasers help lessen reliance on skilled labour in a few key ways:

- UHP laser systems are highly automated and typically come with intuitive HMIs and helpful features, reducing learning curve for new operators

- Built-in cut condition databases, edge-detection tools, automatic nozzle centering, and other systems simplify setup, reduce guesswork and risk of human error

- Cutting precision leads to dramatically improved first-pass quality, meaning fewer parts need to be reworked, saving time and material

- High edge quality reduces or even eliminates the need for secondary processing

- Options to pair UHP systems with automated part loading, unloading and sorting systems, mean you can run efficiently even during labour gaps

Running lean or struggling to hire? Reducing manual touchpoints helps you do more with fewer people. By shrinking your dependency on skilled labour, while maintaining consistent part quality, UHP fiber lasers can help support long-term growth for your shop.

Future-Proofing with Automation Integration

Yes, cutting faster is a key goal when investing in UHP fiber lasers, but it’s not the only consideration. It’s also a way to build a future-ready production system. Being able to scale efficiently through automation is a major strategic advantage.

UHP systems are built to seamlessly integrate with a range of automation tools to help you maximize machine utilization. Think automatic load/unload towers, robotic part pickers, smart conveyors and stacking systems, smart nesting software and warehouse integration. Pairing your UHP machine with systems like these make your shop a powerhouse of production.

It’s smarter manufacturing, not just faster.

Advanced software tools and automation allow you to:

- Operate hours longer, with less human intervention

- Streamline your processes

- Reduce downtime

- Respond more quickly to changes in demand

The speed gains you get with increased power have an even bigger impact when you get smart about automation. You can scale your operation faster, without the growing pains. Take on more volume, without adding cost at the same rate, and with minimal increase in headcount.

So, are Ultra-High-Powered fiber lasers worth it?

With the benefits of speed, quality, flexibility, reduced labour dependency and automation potential, the ROI could be huge. While upfront costs are not cheap, an upgrade could lead to significant long-term savings and competitive advantages. This will depend on the type of work, materials you’re cutting, and volume. Many shops have the opportunity to reduce cost per part over time, while gaining the ability to scale with ease.

Ready to take the next step in fiber laser performance? Contact us to assess whether upgrading to an Ultra-High-Powered fiber laser is right for your shop.

© 2023 Paramount Machinery Inc. All rights reserved.