Blog

RECENT POSTS

PMI Blog

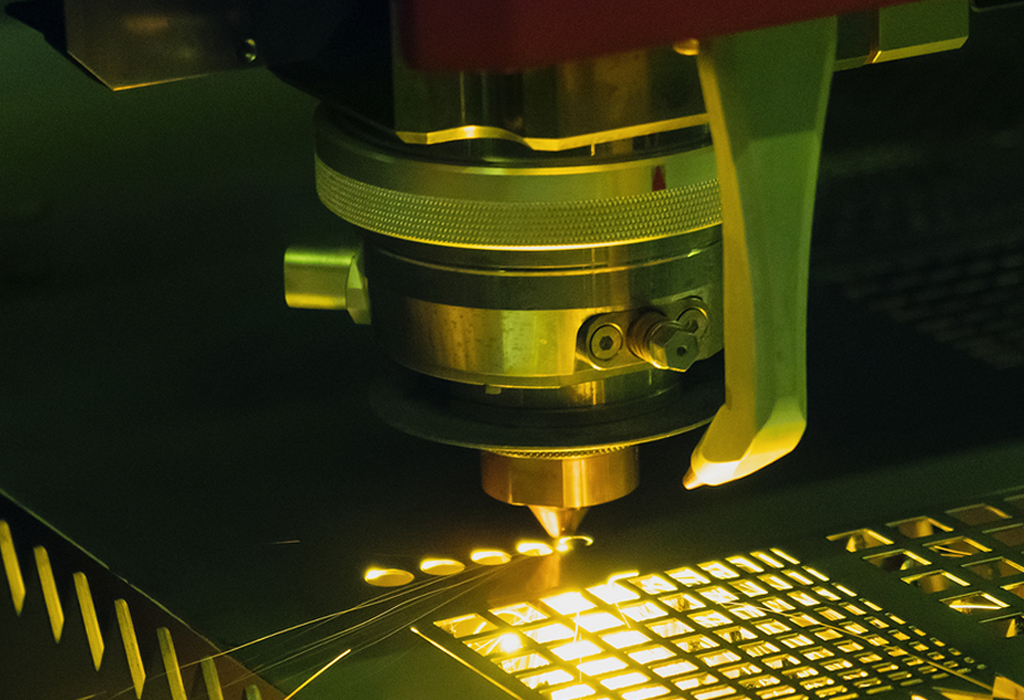

The Top 5 Benefits of Fiber Lasers

by Eric St. James

Published at 2017-11-30

The top 5 benefits of fiber lasers

The industry is constantly evolving and metal fabricators need to plan strategically to keep on top of the competition. With continual advances in fiber laser technology, these machines are becoming increasingly acknowledged as a must-have for fabricators looking to increase productivity and grow their business.

Here are the top five benefits of fiber lasers:

1. Increased Power

Solid state resonators have the capacity to produce almost limitless power. This increased power allows Fiber lasers to process a wide range of materials and thicknesses, reduces the need for oxygen as an accelerant, and boosts cut speed.

Powerful fiber lasers now offer a 12,000W IPG resonator, and have the potential to cut 16 GA mild steel at a rate of 2600 IPM, which was unheard of until recently. This significant leap from the more common 6,000W machines marks a turning point for the industry and sets the stage for even more advancements to come. Big power means higher productivity in fabrication shops, more parts per hour, and most importantly, higher profits.

2. Faster speeds

Fiber lasers offer faster processing speeds to boost productivity levels. The superior acceleration rate of linear motors coupled with higher power resonators allow for faster piercing and cutting speeds. While cutting speeds increase for all materials, fabricators processing thinner sheet metal can reap the most significant advantages, as production rates can double or even triple. Higher cut speeds require a drive system that can keep up. The use of linear motors eliminates the loss of efficiency associated with ball screws or gear drives, for example. They also permit high rates of acceleration and deceleration, leading to shorter cutting times with optimal accuracy.

3. Laser precision

Fiber lasers also display high precision in the cutting process. In addition to faster cutting speeds, they offer advanced beam control for incredible accuracy – even for the smallest, most precise holes. Fiber lasers have the ability to perform complicated piercing routines that include various frequencies, power settings, offset height adjustments, and automatic modification of the beam focus. This not only boosts efficiencies but requires fewer operator interventions and provides better results.

4. Boosted Efficiency

The capability to control the laser for efficient delivery of the beam is a critical feature. According to industry expert Al Bohlen, adjusting and focusing the laser beam can help improve the cutting process. Changing the mode, shape, and heat distribution of the beam could “make a 2,000 watt laser perform like a 4,000 watt laser,” says Bohlen.

Overall, efficiency is one of fiber lasers’ key benefits. Increased power, higher speeds, and greater accuracy allow fabricators to produce more with less, reduce risk, and decrease operating costs for a boost in overall shop efficiency.

5. Low operating cost

The bottom line is one of the most significant concerns for fabricators everywhere. If the efficiency, speeds, power and precision weren’t enough,fiber lasers are also significantly cheaper to operate – up to 50% cheaper than C02 lasers!

Fiber lasers boast a host of factors that dramatically reduce operating and maintenance costs. Solid state resonators are simpler with no moving parts. There are no blowers or vacuum pumps that are costly to replace. Fiber lasers require 50% lower servicing costs and can run 50% longer between servicing.

They also consume less electricity for the same output with high beam quality. Compared to C02 lasers with similar specs, they use about one third of the power on average. Many solid state resonators also “hibernate” when not in use further decreasing power consumption.

As the technology evolves, fiber lasers are becoming increasingly accessible for fabricators. Systems are shrinking with each new innovation, meaning more power from smaller packages. Plus, due to demand and prevalence, prices are dropping – excellent news for fabricators! With all these incredible benefits, opportunities to increase productivity and efficiency, for less overall cost, there’s no better time to switch to fiber laser.

{{cta('849fa231-0b41-4ba1-abb3-6a1718e8c43f')}}

© 2023 Paramount Machinery Inc. All rights reserved.