RECENT POSTS

PMI Blog

When Should You Upgrade Your Shop?

Jan 16, 2024 - Eric St. JamesMany shop owners hesitate to upgrade their equipment and often continue to operate older, inefficient equipment that actually hurts their business bot...

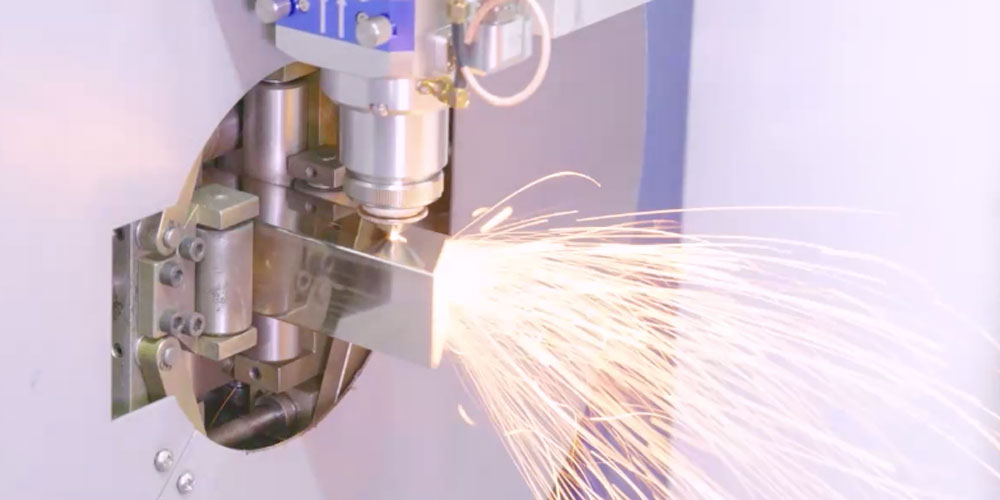

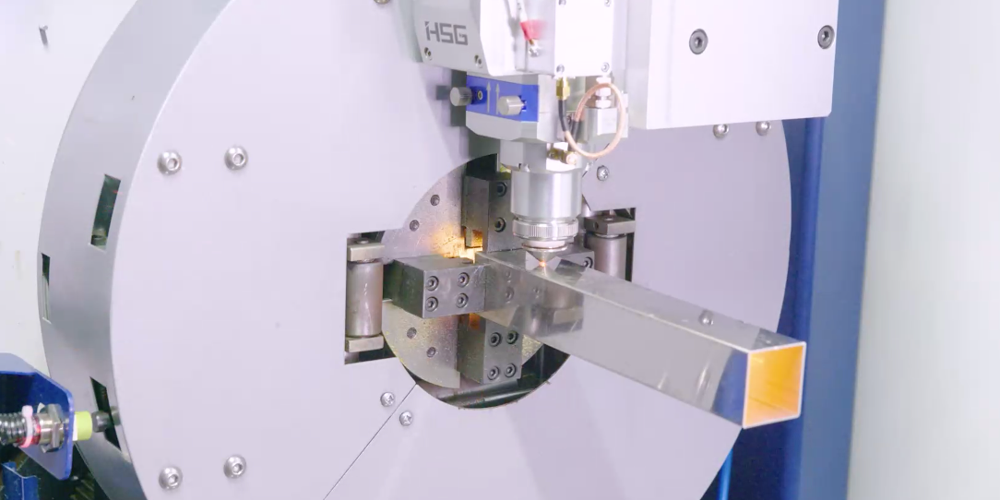

Improving Tube Cutting Efficiency with Nesting

Oct 04, 2023 - Eric St. JamesTube cutting has come a long way and Fiber lasers are largely responsible for that. Laser tube cutting machines have improved cutting efficiencies and...

False Barriers to Upgrade (And How to Overcome Them)

The fabrication industry is fast-moving with increasing pressure to surpass previous standards of speed, quality, flexibility, costs, and service. In ...

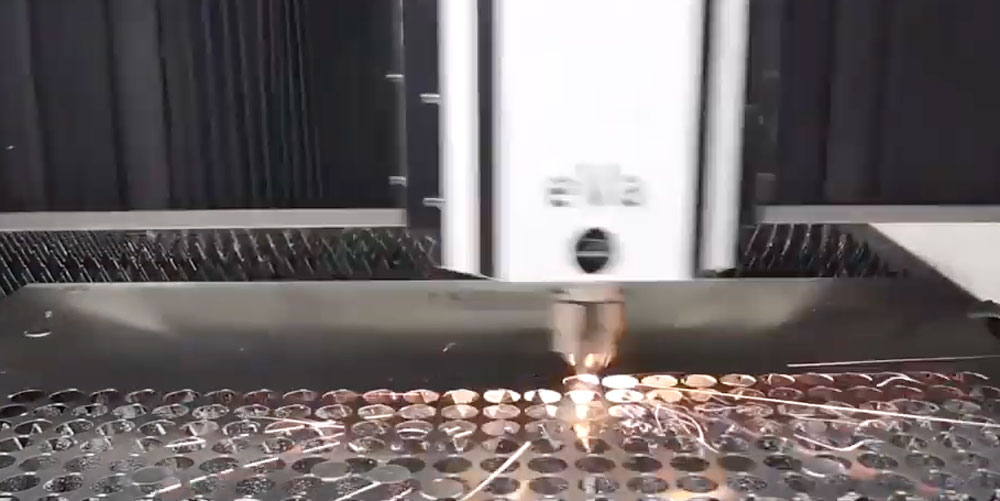

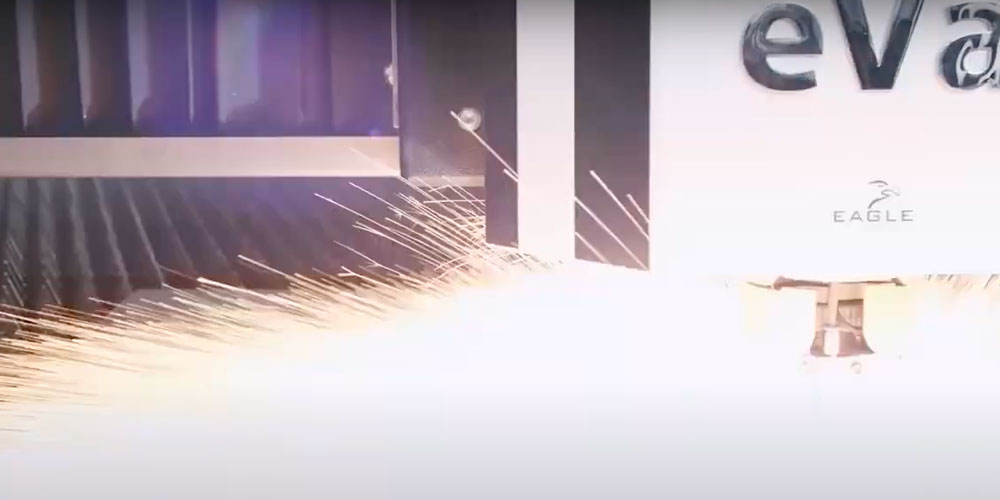

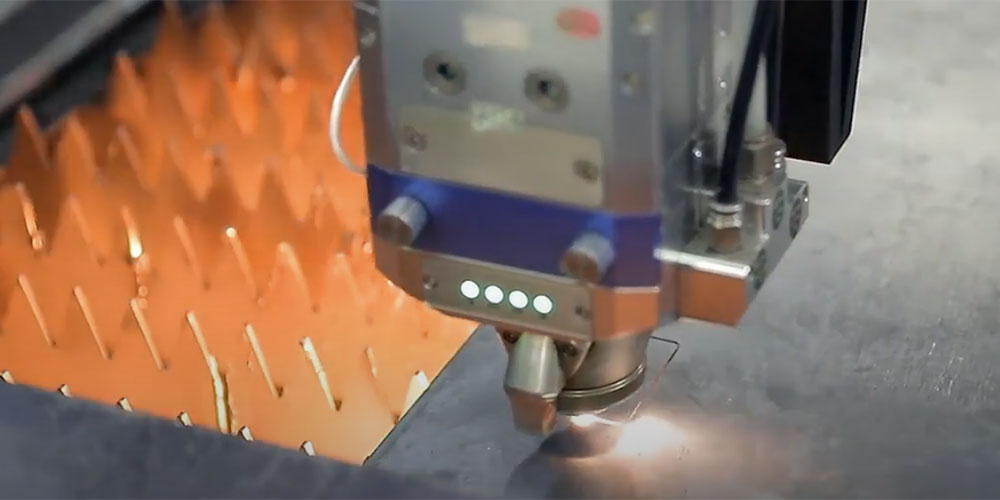

High Powered Fiber Laser Advantages

May 31, 2023 - Eric St. JamesHigh-powered Fiber Lasers (10kW and higher for the purposes of this article) are making their way into the market and quite rightly demanding attentio...

5 Key Parts of Fiber Laser Systems

Oct 05, 2022 - Eric St. JamesFiber laser cutting machines have been rapidly evolving over the past few decades. We’ve seen them increase in power and quickly rise to become a top ...

Why Move to Fiber Laser Tube Cutting Systems

Aug 04, 2022 - Eric St. JamesRecent years have seen fiber laser cutting technology fast replacing traditional CO2 laser metal-cutting processes. New development of high powered so...

Fiber Lasers: Your Competitive Advantage

As we get closer to a post-pandemic world, it’s more important than ever to have a competitive advantage in business. Almost every industry was affect...

Assist Gas Options & Rising Popularity of HPAS

Jun 28, 2022 - Eric St. JamesAn assist gas is required with any laser-cutting process. Primarily, assist gas is used to blow molten metal away from the beam kerf, but it also help...

What an Advanced Fiber Laser System Will Do for Your Shop

Dec 23, 2021 - Eric St. JamesIn today’s landscape, manufacturers are facing a bittersweet reality. On one hand, demand is high. On the other hand, the worker shortage is throwing ...

Increasing Popularity of High-Performance Compressed Air Systems in Fiber Laser Cutting

Nov 30, 2021 - Eric St. JamesAssist gas is essential for all laser cutting processes. Its core job is to blow molten metal away from the beam kerf. This is necessary for all types...

Are Fiber Lasers better at Cutting Nonferrous Materials?

Oct 20, 2021 - Eric St. JamesThe metal fabrication industry is increasingly seeing fiber lasers replace CO2 machines since fiber technology started gaining traction just over a de...

Are Fiber Lasers Eco-friendly?

Sep 14, 2021 - Eric St. JamesIn a world where all eyes are on sustainability, industrial machining and manufacturing are not at the top of the list of eco-friendly industries. All...

Using CAM for 5 and 6-axis Cutting Applications

May 26, 2021 - Eric St. JamesThe art of 5 and 6-axis machining in metal fabrication has evolved over recent years. Using a CNC machine tool to cut along 5 or 6 axes simultaneously...

Metal Cutting Methods and Their Impact on Environment

Apr 14, 2021 - Eric St. JamesAs people around the world become increasingly concerned about pollution, the environmental impact of manufacturing cannot be ignored. Like many indus...

The Importance of Appreciation for your Metal Fabrication Business

Dec 24, 2020 - Eric St. James2020 has been a challenging year for everyone. The COVID-19 pandemic has led to unparalleled uncertainty and stress. Growing health concerns, soaring ...

Fiber Lasers: Less Cooling & Power Requirements

Oct 28, 2020 - Eric St. JamesSave Costs with Fiber Lasers; Less Cooling & Power Requirements Aside from the power, speed and cut quality advantages, one of the top benefits of...

Laser Cutting with Nitrogen and Oxygen: A Comparative Look

Sep 23, 2020 - Eric St. JamesAll laser cutting processes for metal fabrication require the use of an assist gas. Depending on material and application, the assist gas may be activ...

Nitrogen Gas Generation for Laser Cutting

Aug 06, 2020 - Eric St. JamesManaging operating costs for laser cutting machines is a key factor in your shop’s success. Aside from initial equipment investment, one of the major ...

What is Plasma Cutting & How Does it Work?

Jul 10, 2020 - Eric St. JamesPlasma cutting is a popular sheet-metal cutting process that many metal fabricators employ across North America – from large-scale industrial fabricat...

Entry level Fiber Laser Machine for Small Fab Shops

Apr 28, 2020 - Eric St. JamesEveryone in fabrication has been talking about fiber lasers. With superior power, increased cutting speeds and minimal operation costs, it’s easy to s...

Fiber Lasers - Lower Maintenance, Higher Productivity

Apr 15, 2020 - Eric St. JamesWe (and everyone else in the metal fabrication industry) have been discussing the benefits and innovations of Fiber Lasers including incredibly fast c...

Switching from CO2 to Fiber Laser Cutting Systems - What You Need to Know

Mar 31, 2020 - Eric St. JamesFiber lasers have been steadily gaining market share in the metal fabrication industry over the last few years. With several major advantages includin...

Why Fiber Laser Systems are replacing CO2 Lasers in Many Shops

Feb 26, 2020 - Eric St. JamesCO2 lasers have long reigned supreme in the metal fabrication industry. That is until fiber lasers first started gaining traction in 2008 and have bee...

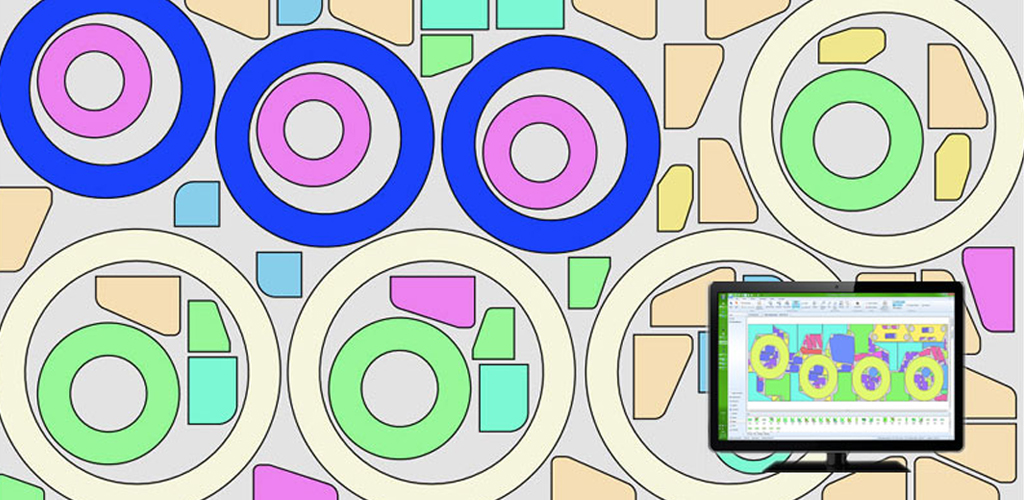

CAM Software - Drive Productivity from the Front Office to the Shop Floor

Jan 16, 2019 - Eric St. JamesThe Role of Cam Software We often talk about how innovations in machinery, like fiber lasers, can boost productivity for fabricators. But what about a...

UHP Fiber Lasers - Are they Worth it!

Jul 09, 2025 - Eric St. JamesLaser cutting has seen incredible advancements since it came on to the scene over 50 years ago. Since the early 2010s, we’ve seen rapid adoption of 1-...

5 ways to show your metal fabrication shop love (and boost productivity)

Feb 09, 2015 - Eric St. JamesAs a metal fabrication shop owner, it goes without saying that your shop is a major part of your life. Like with any relationship, the shop-owner rapp...

How to Implement an Upgrade in your Shop

May 19, 2025 - Eric St. JamesFor many metal fabrication shops, it can be easy to get comfortable with your equipment and technology. With incredible industry innovations in both t...

© 2023 Paramount Machinery Inc. All rights reserved.